Mechatronics Treasure Hunt

Overview

Designing a custom attachment for a 2D Gantry to locate magnets on a table.

Role | Mechatronics Lead | |

Duration | 4 weeks | |

Team | 3 people | |

Scope of Work | Hardware Design, Prototyping, Servo Motor Programming |

The challenge

Create an attachment for a 2 axis gantry that can scan the “ground” using Hall-Effect sensors, identify 5 magnets and then drop a plastic cup on top of the magnets. Try to do this in the fastest time possible.

Context

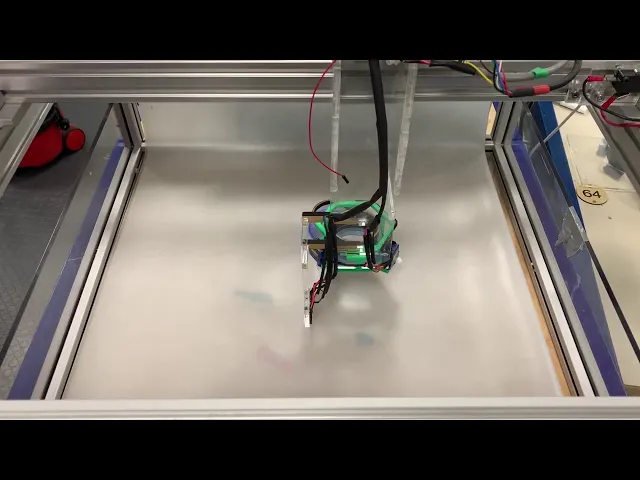

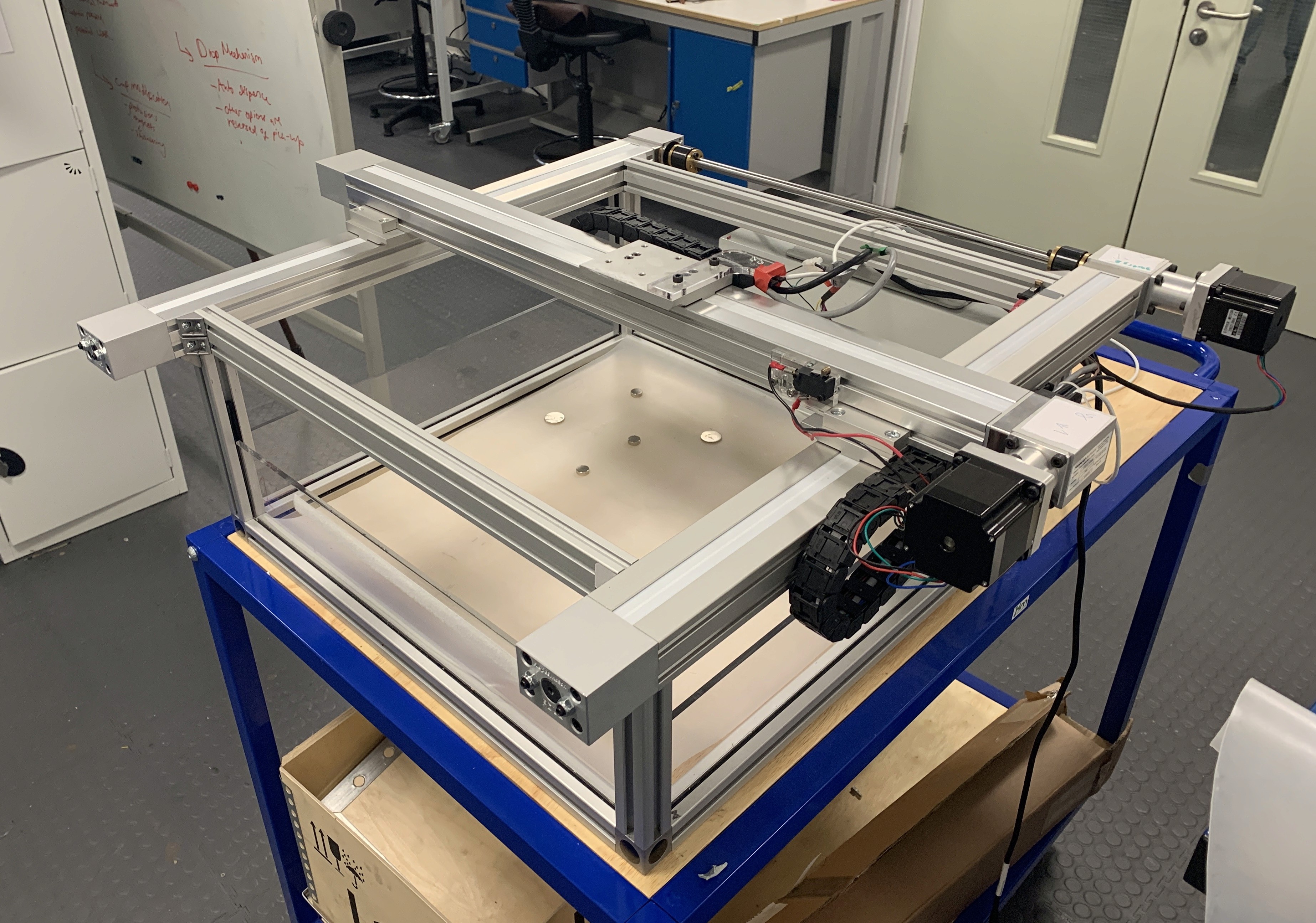

We were given the 2 axis gantry seen below. On Demo Day, 5 flat magnets would be placed under the gantry in random locations. Our goal was to find those magnets using Hall Effect Sensors and place a plastic cup on top of them using a custom mechanism.

Design development

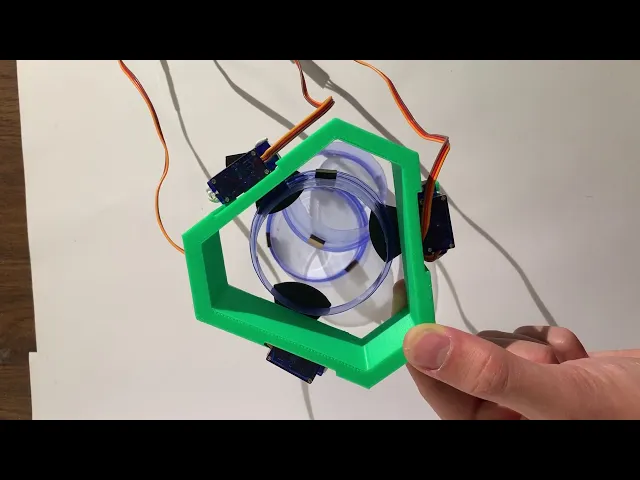

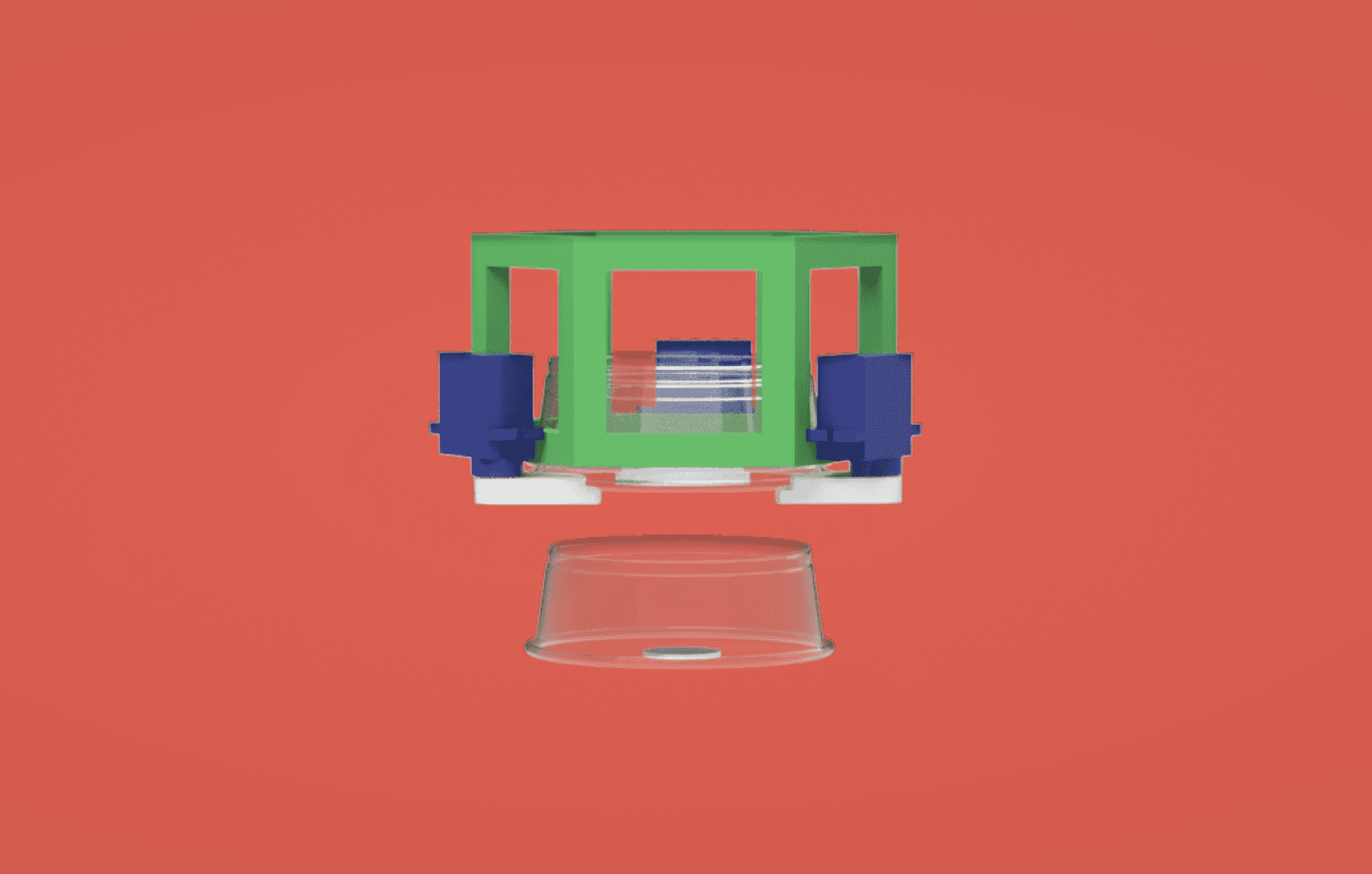

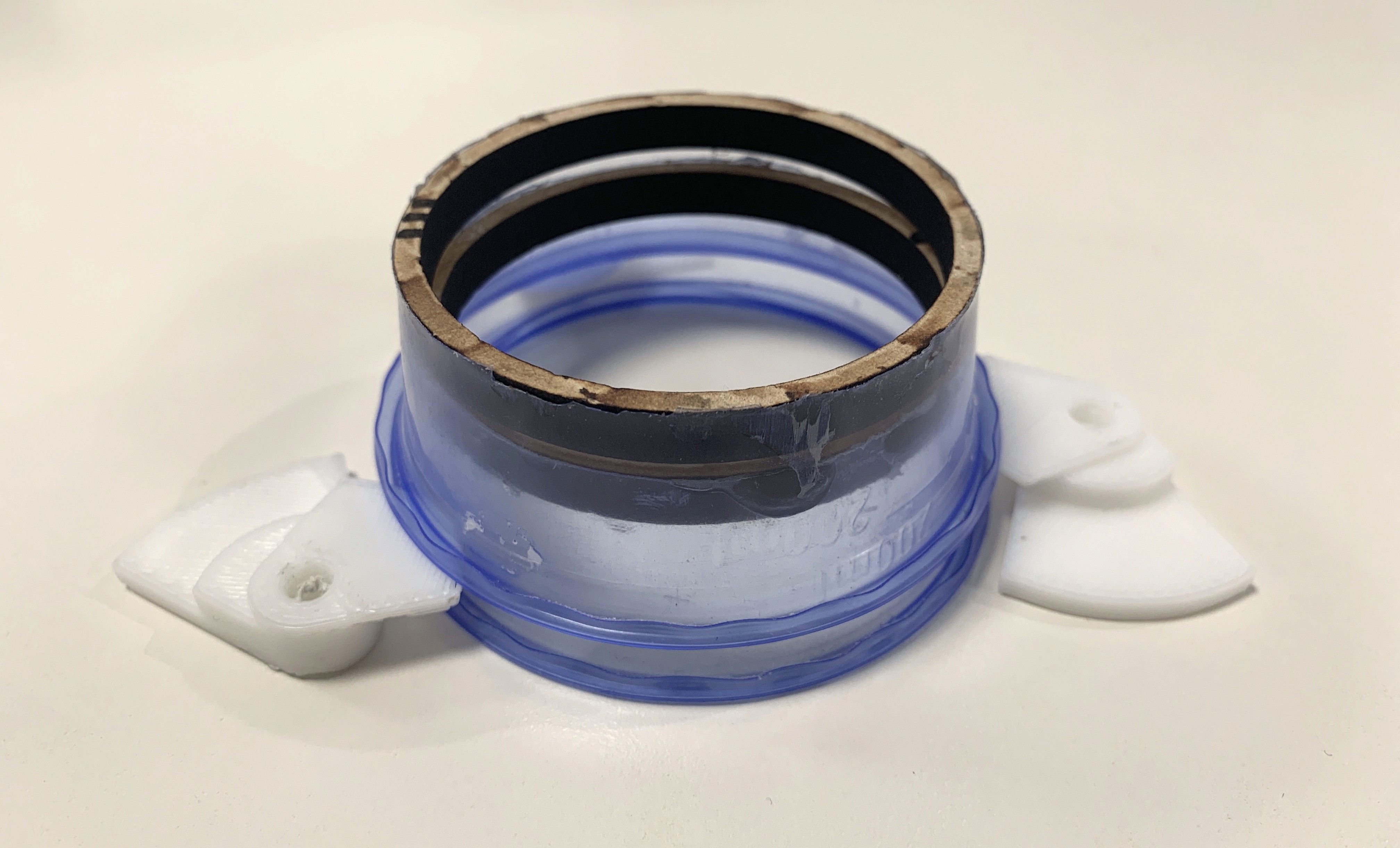

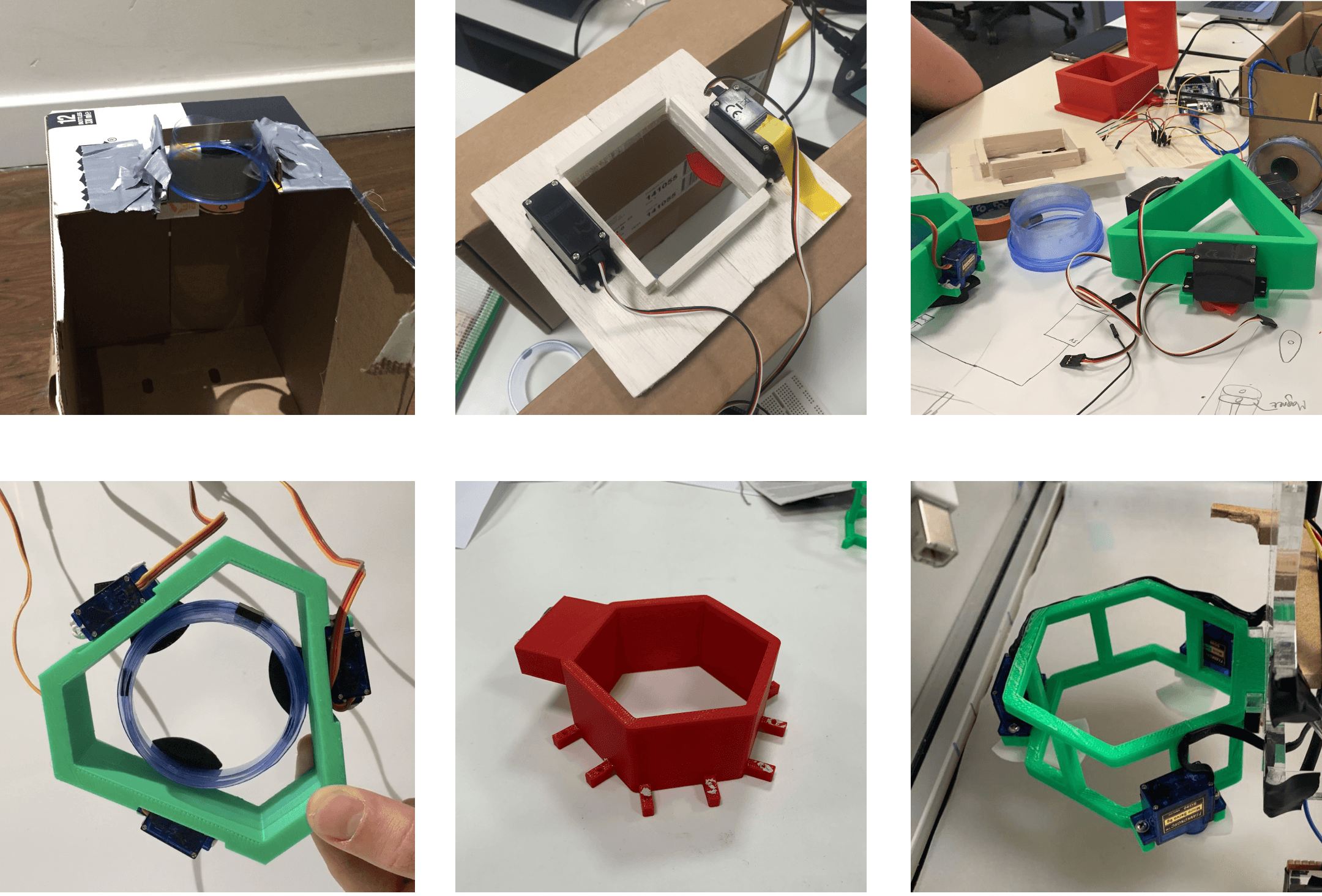

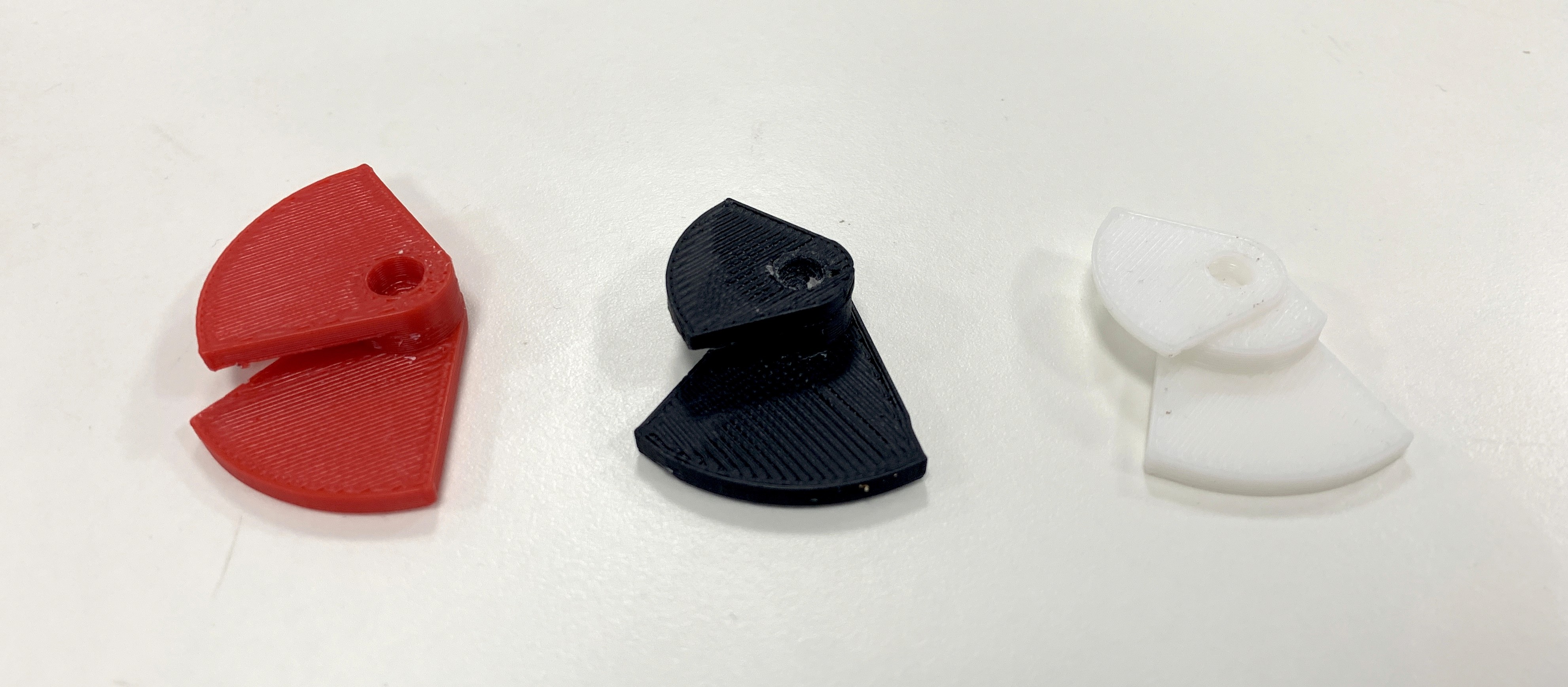

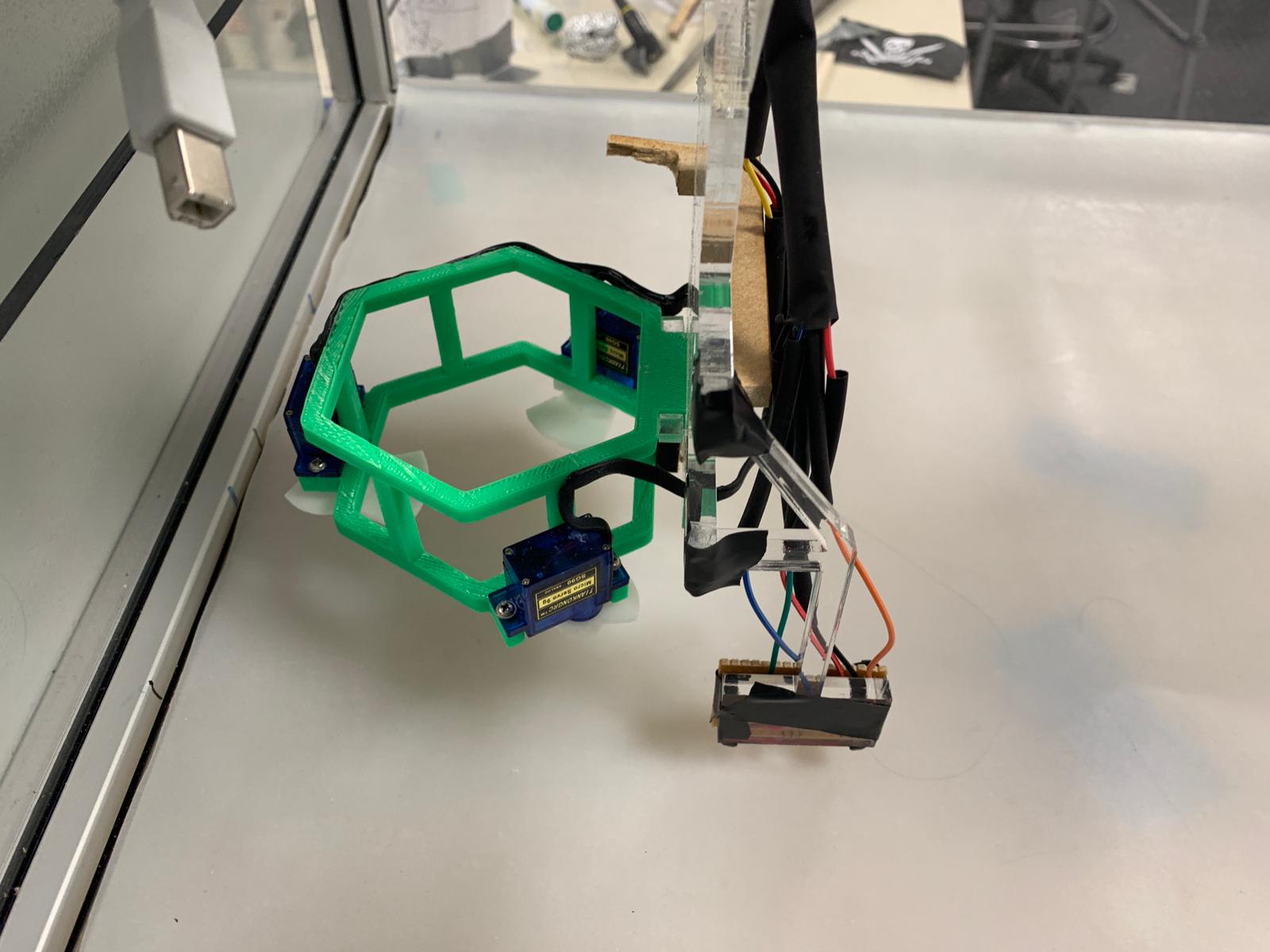

In the team of 3, I was in charge of designing the hardware and electronics used to drop cups accurately after the position of the magnet is detected. Whilst exploring different ideas, I came up with a very simple and compact solution - the smallest out of 10 teams - which only required 3 servos to drop the stacked cups. The design consisted of an optimised 3D printed container with servo actuated fins, which prevented the cups from falling.

By rotating the custom designed fins, the bottom most cup would drop whilst keeping all other cups in position.

When the idea first occurred to me, I built a quick prototype out of cardboard and thumb tacks to test if it was viable. I then went on to build another prototype with balsa wood and actual servos and iteratively improved the design to ensure a stable cup drop and optimal material usage.

Final prototype

The complete attachment scans the ground in a zig-zag pattern, 3 Hall-Effect sensors near the ground detect the magnets and save their position. After that, a cup can be placed on the detected magnet using the mechanism shown previously.

Final demo

Our team achieved the fastest overall time for scanning and dropping of cups, as well as being the most simple design.