b3D

Overview

Creating an automated 3D printing service to allow for continuous printing in workshops across the world.

Role | Project Manager & Part Extraction Design | |

Duration | 3 months | |

Team | 6 people | |

Scope of Work | Project Management, Market Research, Surveying, Prototyping |

The challenge

How can we increase the efficiency of the 3D printing workshop at the university and make it easier for students to submit their prints?

The problem

We started by looking at the current capacity of the workshop at university, the way they operate and what issues they encounter. In addition, we looked at existing solutions - analysing their benefits and drawbacks.

With the growing popularity of 3D printing, the workshop sees an increase in number of print jobs year over year. We found that throughout the semester there were peak periods where the workshop was running at full capacity, with queues of up to a week to print. This was mainly due to the manual nature of the service and limited workshop hours from 8:30am to 4:30pm. Student must bring a USB to a technician which will then setup and start the print on an available printer.

Smart management software and robotic print farms were the two main solutions currently existing in the market that could help solve the problem. Simply using smart software, however, still requires technicians to remove parts from the machines. Print farms consist of a high number of printers which are serviced by an expensive robotic arm or gantry.

User needs

We decided to go deeper into the problem to understand what the students and technicians want out of a 3D Printing service, revealing the points we should focus on. This was done through the creation of user personas, an analysis of the user journey and two surveys being sent out to both students and technicians.

Our proposal

Different top-level solutions were proposed by the team and evaluated taking into account product cost, development time and development cost. The solution shown below was chosen as the best option, consisting of a new 3D printer design which uses a pairing unit (compatible with other printers) to connect with our website, where prints can be submitted remotely. A Minimum Viable Product was designed in 2 months as a proof of concept using a Vertex K8400 printer.

The task was divided into work packages and a team brainstorming session was carried out to come up with ideas for the different aspects of the printer.

Design development

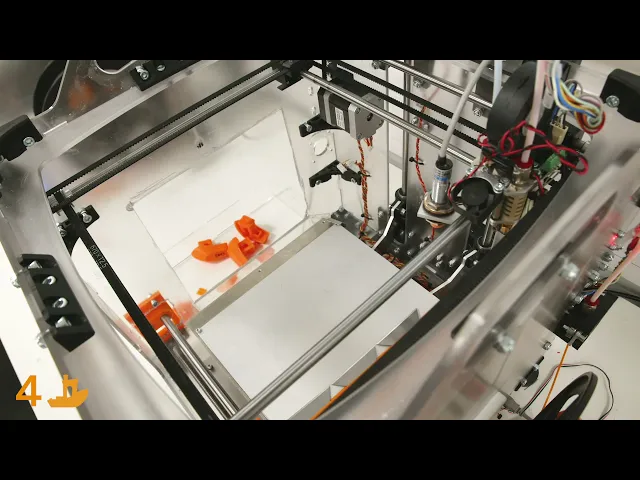

I worked on the creation of an automated part extraction system for the 3D printer. This started by sketching out various different concepts. The concepts were analysed taking into account the available space in the 3D printer and the development cost of the prototype. A leadscrew driven removal blade was chosen as the design to develop further.

The design went through several different iterations, where different blades and "blade-holder" designs were tested. This work was carried out alongside other team members who integrated additional features such as a Heated Print Bed for easier removal, a bed calibration system to ensure prints didn't fail and a filament monitoring system to alert a technician before the filament runs out. Tests were carried out to determine how different print sizes affected removal force.

Final Prototype

The final prototype was presented at the University's design exhibition, where people were invited to print remotely from our website, adding the job to an online queue and receiving a notification when their print started and finished.